How-to & Style

All opinions or methods expressed in the video(s) are personal opinion only and for educational purposes only. Always check current regulations or seek second opinions from other video sources or websites. Anyone working at ANY height should be fully trained and insured to do so and use the correct access equipment. Anyone working on ANY project does so at their own risk!

Mixing a small sand and cement bucket mix like this by hand is not only fast, but very cheap for small DIY jobs around the house. A lot of repair jobs even for professionals involve 'knocking up' small amounts of mortar like this. This is I believe an essential life skill, like knowing how to wire a plug, or unblock a sink.

Great for small pointing jobs, pointing lead flashings, brickwork chases, walls and chimney to name but a few...

For lager jobs why not consider a builders spot mix : http://youtu.be/ehBKETtRImk

For more help with common sand and cement mixes : http://www.fixmyroof.co.uk/mix-cement-mortar/

To learn how to point up a wall, slabs or chimney se this video : https://youtu.be/jPcp0iLoJtM

A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource.

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are recombined into new compounds. The result is called clinker, which are rounded nodules between 1mm and 25mm across. The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement. The powdered cement is then mixed with water and aggregates to form concrete that is used in construction.

Clinker quality depends on raw material composition, which has to be closely monitored to ensure the quality of the cement. Excess free lime, for example, results in undesirable effects such as volume expansion, increased setting time or reduced strength. Several laboratory and online systems can be employed to ensure process control in each step of the cement manufacturing process, including clinker formation.

Video Credits: www.ohorongo-cement.com

Join 'Engineering World' like many others to get access to special perks:

https://www.youtube.com/channe....l/UCh2wZoBynUkHmTX2G

Also, kindly consider subscribing to our channel if you liked the video: https://geni.us/SubscribeChannel

Watch some of our other interesting manufacturing videos:

How Plywood Is Made In Factories?

https://youtu.be/3Wh9NYvfStk

How LUXURY Rolls-Royce Cars Are Made ?

https://youtu.be/BVvnSzMqI3M

How Jigsaw Puzzles Are Made?

https://youtu.be/nylElsB9MkE

This video tutorial details the process of making a Poly 75-70 polyurethane rubber mold of a concrete stepping stone. In this example, we utilize the "poured block mold technique", which is considered to be one of the most simple mold making methods.

Although the stepping stones in this scenario can be easily replaced through options at retail stores, this mold making method is great when you have a unique stone that is not replaceable OR when you'd like to produce custom pavers from your original design (made from wood, clay, a printed model, etc.).

A full list of materials and tools used for this project can be found at the end of the video.

The Steps:

1. Select a Model [0:32]

2. Apply a Sealing Agent (Poly PVA Solution) [0:53]

3. Prepare Model and Construct Mold Box [1:24]

4. Apply Release Agent [3:33]

5. Calculate Amount of Rubber Needed for Mold [4:13]

6. Measure, Mix & Pour Mold Rubber [5:03]

7. Demold [6:29]

8. Cast Concrete [7:24]

http://www.polytek.com

http://www.facebook.com/polytekdevelopmentcorp

http://www.twitter.com/PolytekUSA

You can use concrete paver blocks as edging for your garden beds, or to give your driveway a makeover.

In this video, I'd like to share how I make concrete paver blocks using plastic molds. Also included are tips on how to demold properly so that you can minimize your chances of damaging the resulting blocks.

The plastic molds I used come in different shapes. In the video, you'll find 3 options. Get these paver molds here: http://s.click.aliexpress.com/e/rqYgPVRi

#HowtoMakeConcretePavers

#HowtoUseConcretePaverMolds

This is a great beginner project for dipping your toes into concrete projects! I go over the steps to create basic concrete shapes and forms, and pouring. No crazy steps or perfection needed since it's just a block, so have fun and practice!

I know they are inexpensive to buy, but around here they go out of season, or you may need a shape or size they don't sell, so this can come in handy for different situations.

Help support the channel and the things I can show by using the links below, it costs nothing to use them, but helps me out so I can help you!

Get the Freshest CA Super glues in the market at Starbond (https://bit.ly/2KPcQTa)

Use Code CANADIYAN at checkout to save 15% off on your purchase!

**************************************

Jesse Does DIY links:

🛠Email: jessedoesdiy@gmail.com

🛠Project Plans: https://jessedoesdiy.etsy.com

🛠Instagram: https://www.instagram.com/canadiyan_jesse/?hl=en

🛠Instructables: https://www.instructables.com/....member/Jesse+does+DI

Other Channel with Slade:

https://www.youtube.com/channe....l/UC-qQtqcjoWHbNn9Kg

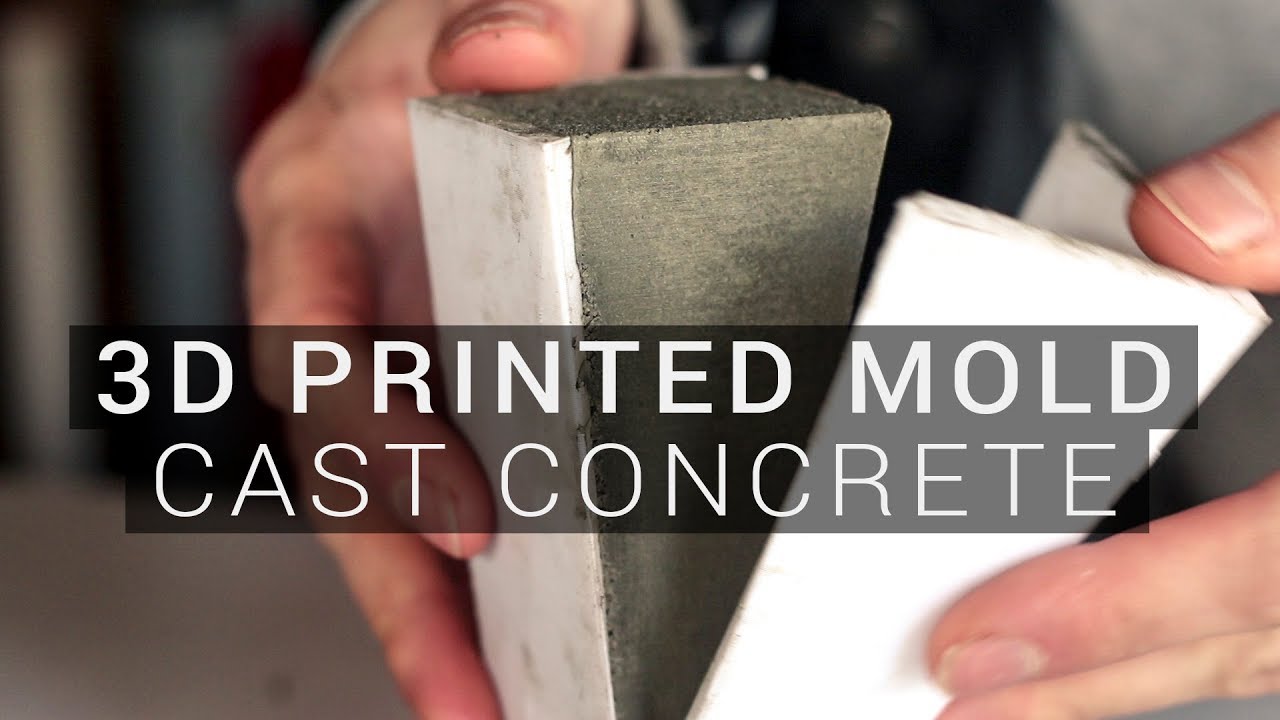

How to use 3d printed molds to create cast concrete products and objects - without needing any silicone.

All Project files are available free from my website:

https://www.furtherfabrication.com/resources

Find me on instagram:

https://www.instagram.com/further_fabrication/

Link to Fusion 360 software:

https://www.autodesk.com/produ....cts/fusion-360/stude

Music:

https://www.epidemicsound.com/

PRODUCTS USED IN THE VIDEO DOWN BELOW

Molds- https://bit.ly/3K19aJ1

Heavy Duty Bucket- https://bit.ly/3K4pc4Z

Mixer- https://bit.ly/3wCny7r

Vibration Table- https://bit.ly/3QJIXTd

Vibration Motor For DIY Vibration Table- https://bit.ly/3WZ7Oq7

How to make Silicone Molds for cement, concrete, wax, soap or plaster castings. Easy DIY project and great way to make multiple reproductions of almost any small to medium sized item that has one flat surface.

Check out our other DIY projects.

WEB http://www.diyeasycrafts.com/

Please join us on:

FACEBOOK https://www.facebook.com/groups/1668357033451028/

PINTEREST https://www.pinterest.com/wrec....kvalle/diy-easy-craf #DIYeasycrafts

Take the full course - https://proko.com/sculpture

Can you create a good mold of your sculptures at an affordable price? Yes, yes you can! In this lesson Andrew covers the materials needed to make a quality mold and the step by step process for making it. You’ll see how to apply the silicone to your sculpture and then the process of pulling the sculpt from the mold, and filling it with resin. If you enjoy this lesson and want the more in-depth one check out the premium course (link above).

Your assignment is to create a mold of a torso. If you don’t have one, sculpt one and then make a mold. We’d like to see what you come up with so make sure you post your work here - https://proko.com/712

RELATED LINKS:

7 Types of Sculpting Tools and How to Make Your Own - https://youtu.be/7MT-zYpPCGg

5 Ways to Add Texture to your Sculptures - https://youtu.be/BnyOSYXjYVw

Basic Sculpting Supplies - https://youtu.be/L1kCB4Ahqrk

#moldmaking #sculpting #siliconemold

COURSE DESCRIPTION:

This portrait sculpting course will dive deep into the techniques and principles that will help you master the portrait. Portrait sculpting is one of the most difficult challenges that visual artists can take on but if you follow the lessons and do the corresponding assignments you'll be surprised how fast you will improve.

ABOUT PROKO 3D:

Instructional How to Sculpt videos for artists. These sculpting lessons are approachable enough for beginners and detailed enough for advanced artists. My philosophy is to teach timeless concepts in an entertaining way. I believe that when you are having fun, you learn better. I take pride in producing high quality videos that you will enjoy watching and re-watching. If you want to learn more about drawing check out my other YouTube channel: Proko - https://www.youtube.com/ProkoTV

CREDITS:

Artist | Instructor - Andrew Joseph Keith (https://andrewjosephkeith.onuniverse.com)

Producer - Andrew Joseph Keith, Charlie Nicholson (https://www.instagram.com/shloogorgh/)

Script & editing - Andrew Joseph Keith

Model images courtesy of https://www.pixabay.com

How to make a concrete planter making a cement pot mixing concrete

Connect with me on IG https://www.instagram.com/tedsbackyard337/

Music:

"Acid Jazz" Kevin MacLeod (incompetech.com)

Licensed under Creative Commons: By Attribution 3.0 License

http://creativecommons.org/licenses/by/3.0/

"Poofy Reel" Kevin MacLeod (incompetech.com)

Licensed under Creative Commons: By Attribution 3.0 License

http://creativecommons.org/licenses/by/3.0/

"There It Is" Kevin MacLeod (incompetech.com)

Licensed under Creative Commons: By Attribution 3.0 License

http://creativecommons.org/licenses/by/3.0/

"That's a Wrap" Kevin MacLeod (incompetech.com)

Licensed under Creative Commons: By Attribution 3.0 License

http://creativecommons.org/licenses/by/3.0/

PLEASE ENJOY A MORE UPDATED VIDEO ON THIS CONTENT: https://youtu.be/Wok4O6Hm79g

Hey guys! Today’s video is another voiceover, as I sound pretty muffled when I have my mask on lol! Hope you enjoy!

How to make concrete jars video: https://www.youtube.com/watch?v=LNnEJ5kUaIU

Sealing video: https://www.youtube.com/watch?v=8udk7cHaEGE

Please note that everything shown in this video is just what works best for me. There is no wrong or right way of doing things. I urge you to do your own research and testing.

WEBSITE: https://www.calafiacandleco.com (enjoy 15% off with code "YOUTUBE15")

INSTAGRAM: https://www.instagram.com/calafiacandleco/

FACEBOOK: https://www.facebook.com/calafiacandleco

TIKTOK: https://www.tiktok.com/@calafiacandleco

SHOPIFY (I could not run my business without this platform!):

https://shopify.pxf.io/jrrEm0

AMAZON STOREFRONT: (All supplies I use from Amazon are linked here)

https://www.amazon.com/shop/calafiacandleco

CHECK OUT MY DIGITAL DOWNLOADS:

https://www.etsy.com/shop/CalafiaCreative

INVENTORA (Referral link):

https://inventora.co/?via=bree

MAKESY (Referral link):

https://makesy.com/?rfsn=7664659.22f821a

“THE WINNING FORMULA” ONLINE CONCRETE CANDLE JAR MAKING COURSE FROM UP VIBE (JAI CATALANO) [Referral link]:

https://theupvibe.com/?wpam_id=4

30 DAY FREE TRIAL EPIDEMIC SOUND (WHERE I GET MUSIC FOR MY VIDEOS)

https://share.epidemicsound.com/ox04b3

OTHER SUPPLIES:

• Modern Craft Labs mold: https://moderncraftlabs.com/pr....oducts/3-tulip-silic

Canadian Silicone Molds: https://www.canadiansiliconemolds.com/

• Cement-All: https://www.homedepot.com/p/Ra....pid-Set-55-lb-Cement

• Distilled water: https://www.target.com/p/disti....lled-water-1gal-good

• Concrete pigment: https://directcolors.com/concrete-pigment/

• Earth Safe Finishes: https://bit.ly/46vqIHe

• Preserver/Sealer: https://bit.ly/3PEO4UH

• Quick Dip: https://bit.ly/44ou64T

• Quick Dip Matte: https://bit.ly/3DDf6EX

• Northwood Distributing: https://northwoodcandlesupply.com?ref=bree_marble (referral link)

• Coconut 83 wax: https://www.hiveandhoneycandle....co.com/CALAFIACANDLE (referral link)

• SP 487 wax: https://www.hiveandhoneycandle....co.com/CALAFIACANDLE (referral link)

• Norden wick centering kit: https://nordencandlesupply.com..../products/wick-cente

• Label Ledge: https://label-ledge.com/

• Labels: https://www.onlinelabels.com/

*some links are affiliate links*

How to make a wooden mold for concrete pavers mobile home build.

In this video, you can see how I made a wooden mold.

-First I made a template

-Then I cut the wood for the mold

-I then assembled and screwed the mold

So the mold was ready for work I can start mixing the concrete.

I found that the best mix of cement and sand for concrete is 3 parts sand to one part cement. Water by feeling.

And so I make a patio in front of my mobile tiny house build.

To finish this tiny mobile home I need about two more months. And then we have to find another tiny mobile home project.

Stay tuned for more tiny mobile home builds!

Thanks for watching and see you in the next video!

Related video:

https://youtu.be/aZ8ObrpBj6Y

https://youtu.be/rvMpGdIMcEs

https://youtu.be/FvSdBHAl5hc

Uploaded to this channel are not how-to videos.

All work is done in a personal and self-responsible manner.

You can support the channel here:

https://paypal.me/robertklemen....sberger?locale.x=en_

Hi everyone, today I'm going to do some cement craft. These items will be send to as gifts. I make it as a tutorial so that some beginner for cement can follow this method step by steps. Enjoy~

-----------------------------------------------------------------------------------------------------------------------

Materials can be found here:

👉🏻 Trinket tray mold: https://s.click.aliexpress.com/e/_o2FC8OF

👉🏻 Cylinder mold: https://s.click.aliexpress.com/e/_oCFPuYX

👉🏻 Soap dish mold: https://s.click.aliexpress.com/e/_oow9xRZ

👉🏻 Acrylic paint: https://s.click.aliexpress.com/e/_mM1rL4e

👉🏻 Epoxy resin pigment: https://s.click.aliexpress.com/e/_mKjR61U

-----------------------------------------------------------------------------------------------------------------------

♡ Step by Step Cement Terrazzo Holder: https://youtu.be/WljHKeiR17Y

♡ Type of Sealants: https://www.youtube.com/watch?v=KrGiUwKG-vM&t=0s

♡ Which Sealant Better: https://youtu.be/29-ztNXrHfs

♡ Easy Marble Tray: https://youtu.be/LNJtUa2qsBc

♡ Colour pigment for cement: https://youtu.be/eGBzEbpgiy8

♡ Cement Q&A: https://youtu.be/qU3MXX9hCOI

------------------------------------------------------------------------------------------------------------------------

❤️ Simply click the like and share button to support my channel to grow.

❤️ You may also hit the "Thanks" button if you want to buy me a coffee

------------------------------------------------------------------------------------------------------------------------

Artist : 오늘의 일기

Link : https://youtu.be/4zfyTfQa0uw

A rubber mold for concrete statues will fail without an outside support, which is where a fiberglass mother mold (shell) is essential. The fiberglass can hold the massive weight of concrete, and it will hold the form until it hardens for demolding. It also is light and easy to use, allowing for quicker statue production. This video will give a detailed demonstration, along with tips and ideas, for creating an effective "mother mold" for creating concrete statues.

Concrete garden statues and other art, whether animals, gnomes, or seasonal figurines, enhances the garden, patio, or yard, it lasts forever, and it also makes an ideal gift. This video series will guide you through the process of making a mold for concrete statues and other art forms. You will be taught tips and methods for casting a mold of almost any item, from start to finish!

NOTE - This is the second in a set of videos on how to make concrete garden art from start to finish. Check out the channel to see the 3rd video on how to use a rubber mold with the fiberglass shell to cast and then finish a new statue for outdoors. Here is the playlist: https://www.youtube.com/playli....st?list=PLJZYCSTvzuh

Backyard Adventures with Andy Wright is a channel devoted to all-thing gardening and yard care, along with random "adventures" that include statue making, building a pizza oven (coming soon), home entertainment tips, and more. Tune-in for some inspiration and instruction on all things home and yard!

Focus Questions: How to make a fiberglass mother mold to support a rubber mold in casting statues?